Alan's Model Railway Pages

2020

The Model Railway on the pages further down is now no more. The

baseboards started to warp as they were too thin and so the

complete

layout has been dismantled.

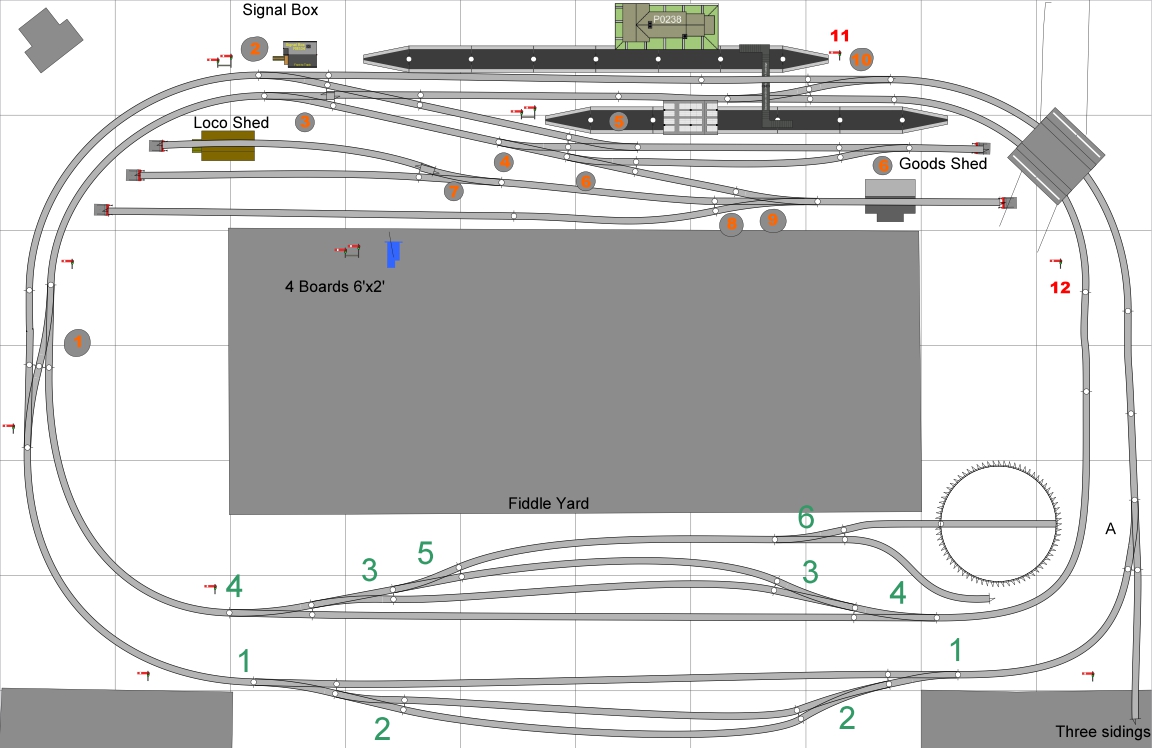

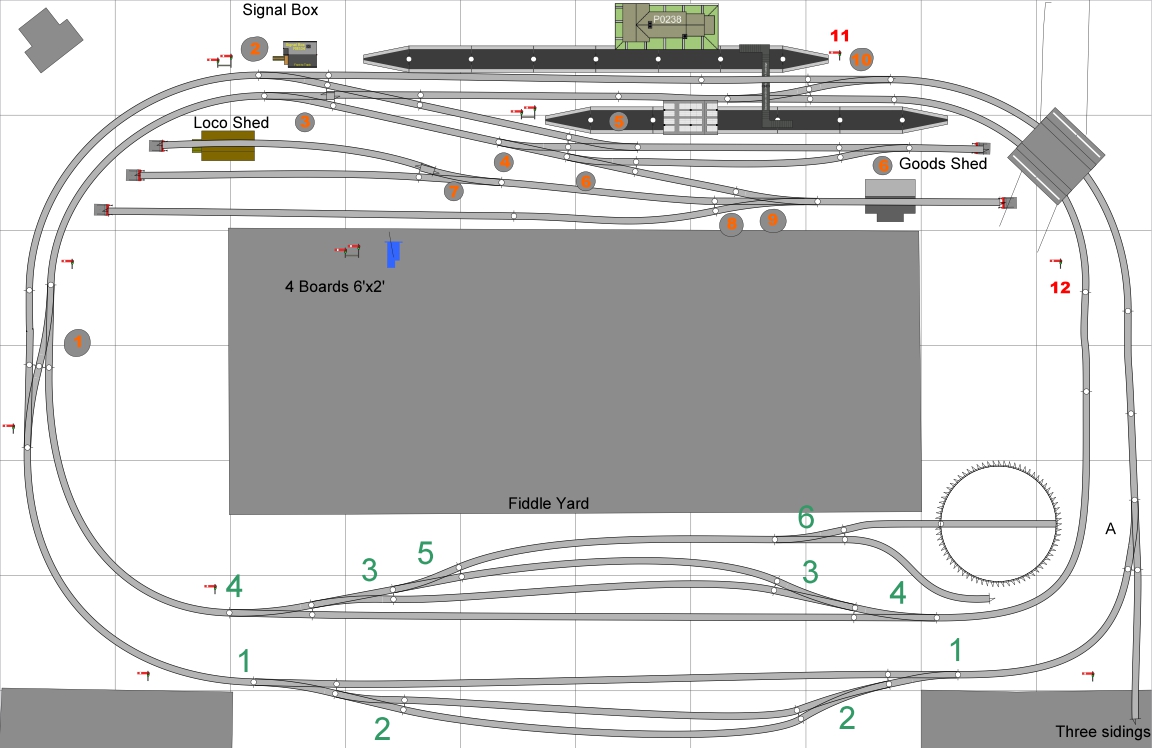

BUT I have purchased four professionally made base boards (Model

Railway Solutions) each 6' by 2' to make a layout 10' by 6'

which is more compact and takes up less room in the loft.

The layout plan is here:-

Latest photos September 2022

The new baseboards are now in position:-

I have finished laying all the cork underlay and can soon start

on track laying - 25 Sept 2020.

Majority of track now laid and most of the Cobalt point motors in position at 24th December 2020.

Awaiting new back scenes (Taller & Wider) and when track laying is complete and ballasted can start on the scenics.

I am now awaiting all the Cobalt Point Levers and also the Peco

Twistlock point motors all delayed due to covid. 24th December 2020

Cobalt Point Levers now arrived (5th January 2021) so I can now start connecting all the wires to the Cobalt Point Motors.

They have to be mounted properly, painted and numbers etc. added.

Making progress with scenics now that all electrics are complete and

working. Not very good at ballasting and there is a lot to do!

July 2022. Hot in the loft so overall progress is very slow.

More scenery completed July 2022.

I am

gradually replacing many of the Peco solenoid point motors with

these Cobalt motors. They are superior in nearly every respect and

are ideally suited to DCC and also Computer Control. They also

have two inbuilt SPDT switches for frog power switching, indicator

panels or signals.

I am

gradually replacing many of the Peco solenoid point motors with

these Cobalt motors. They are superior in nearly every respect and

are ideally suited to DCC and also Computer Control. They also

have two inbuilt SPDT switches for frog power switching, indicator

panels or signals.

2013

Now that I have five grandchildren (all boys) it seemed

like a good idea to build a Model Railway.

We have a large loft with good headroom so after clearing out

some rubbish (a lot remains to be sorted) I set about the task in

February 2009.

The plan always was to have computer control of the Model

Railway eventually. Sadly, I recently discovered that the

Gaugemaster DCC Controllers that I purchased at the start do NOT

allow for computer control.

I have decided now to replace all my Gaugemaster systems with the

NCE Powercab System. I have also decided to use the Big Bear

software for computer control of the railway. Below is the control

diagram on the laptop computer that will eventually control the

railway (Manual control will also be available). The diagram

covers the main staion area, the goods yard and the engine shed

and turntable. The fiddle yard on the other side of the railway

will remain under manual control.

The space allows me a layout

20' x 10' around the edge of the loft at about waist height.

This is the basic layout plan. I wanted

to have a continuous run with up and down main lines but also

a branch line, goods yard and engines shed!

In other words - the lot!

The main boards are 30" wide and the fiddle yard boards 18"

wide. Height is 42" 6mm board made up with 2" x 1" frames and

all mounted on a 2" x 1" H legs. I already had a few locos,

carriages and trucks so after buying some Peco Code

75 track

I made a start. The model railway is to be DCC controlled

as that seems to be the best way to go

nowadays. Also being

into computers the idea of computer control at some point seemed

attractive.

I have been busy building a tunnel at one end of the layout to

lead to the fiddle yard. Traditional construction using a chicken

wire core with

plaster cloth on top painted brown and finished with green flock

of various sorts and a few trees. Have also completed two railway

cottages,

and an Inn. Have laid out a garden for one cottage. Beginning to

stock up with a few motor vehicles.

Class 31

The station area is coming on. The 2 aspect coloured light signals

are working but the fine details (ladders etc.) will be added

later.

My son Gareth bought me some Traintronics two aspect signals for

my birthday. I purchased more signals and all the bus

wiring from Express

Models.

I also have some MSE semaphore signal kits and some Ratio signal

kits to build.

Coal Yard closeup.

British Railways Standard Class 5 (Weathered)

Bulleid Pacifics are my particular favourites - both rebuilt and

air-cased.

British Railways Standard Class 4 and Bulleid Q1.

I have a lot of work to do on the roads. Also the many buildings

need chimney pots and the cinema has to be finished!

I have working lights for roads and the station but they are

waiting installation. Platform signs and posters are also needed.

The Goods Shed needs its roof, doors and finishing.

Coal Yard

I ordered a SR branch signal from Stephen Freeman. The layout now

has a mixture of semaphore signals and coloured light (two aspect)

signals.

They are all connected up through Heathcote

Electronics IRDOT infrared train detectors and IRDASC

circuit boards.

Each of these in turn connects to the previous signal. The

signals turn to danger after a train has passed and back to green

when

the train has cleared the next section. The coloured light signals

work directly off the detector boards while the semaphore

signals need the servo control boards to operate the signal arms.

All this means that whoever is driving a train has to obey the

signals or collisions might occur!!

The new signal is now in position.

A better view of the new signal made for me by Stephen Freeman

of Borg Rail. It is

fully working with lights and servos

but they are not yet connected.

Bulleid Q1

The church and tunnel at the other end of the layout. Much work

still to do here. The temporary LED signal lights

are to be replaced with a working semphore signal. This is

in the workshop being finished at the moment.

Lytch Gate still come for the church. Level crossing and roads to

be finished.

Gardens, driveways etc. to be finished. Pathways to be layed.

I might get the level crossing gates to work one day!!

Signal now in position and working

New Yard Lamps - 6v wired in series. Now all working

A Station Platform view.

A goods train passing through the station. Cinema still to be

finished.

I have also now put up some backboards in plain blue. I hope

eventually to purchase some country scenes to paste upon these.

Also some front boards to hide all the wiring. There is a main DCC

bus running all around and providing many track feeds.

There is also a 12 volt DC bus all around providing power for

points, signals and lighting. More of his later.

The platforms are made fom the Metcalfe kits as is the Station

building and some of the house and shops etc.

Here is progress before ballasting.

I have built a number of Metcalfe card buildings, which are

excellent and also purchased some Hornby Skaledale buildings

and a couple of Bachmann buildings. I have started

ballasting the track with different colours of N gauge ballast

using the

age old method of fine water spray, PVA glue etc.

After investigating the various DCC Control systems available I

decided on the Gaugemaster Prodigy Advance 2 system.

I now have three walkabout controllers and it is also connected to

the Gaugemaster software on and old laptop computer.

I have built a small desk on which to place the controllers along

with a spreadsheet showing all the loco numbers and routes.

I also decided to use Micro Miniatures http://www.microminiatures.co.uk/acatalog/IR_Points_Motor_Controller.html

infra red point controller. Again this seemed like a good idea at

the time but now I discover that it cannot control Tortoise

or Cobalt point motors. I have made up a display panel which shows

the position of every point on the main layout.

Normal point position is shown by a green led and change position

by a red led. Routes can also be set with this system.

Here is the basic setup. The loft still needs an aweful lot of

clearing out and tidying up!

The start of tracklaying

Unfortunately I started track laying on the main station area. I should have started with the fiddle yard side until I had a

little more experience of tracklaying and ballasting. I also decided that electrofrog points would be best worked with

Peco PL10 point motors. I did not make proper allowance for powering the frogs. This I am now regretting .

I am

gradually replacing many of the Peco solenoid point motors with

these Cobalt motors. They are superior in nearly every respect and

are ideally suited to DCC and also Computer Control. They also

have two inbuilt SPDT switches for frog power switching, indicator

panels or signals.

I am

gradually replacing many of the Peco solenoid point motors with

these Cobalt motors. They are superior in nearly every respect and

are ideally suited to DCC and also Computer Control. They also

have two inbuilt SPDT switches for frog power switching, indicator

panels or signals.